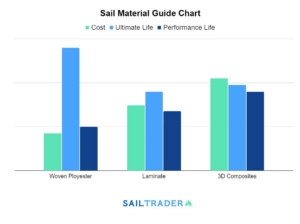

We live in a sailing era where technology is advancing at incredible speed, and when it comes to sailcloth, it can be hard to navigate the wide selection of products available on the market. From the more traditional woven Dacrons to high-tech 3D composites, every material has its advantages and disadvantages, and what suits one sailor and their sailing application, might not suit another.

We live in a sailing era where technology is advancing at incredible speed, and when it comes to sailcloth, it can be hard to navigate the wide selection of products available on the market. From the more traditional woven Dacrons to high-tech 3D composites, every material has its advantages and disadvantages, and what suits one sailor and their sailing application, might not suit another.

In this short and comprehensible guide, we will be going over the various sail construction and materials used for making mainsails and headsails for both the racing and cruising markets.

If we could imagine a perfect mainsail or headsail, it would be made from a cloth that is immensely strong to withstand the loads in harsh conditions. It would be flexible to handle some flogging and flaking when put away. It would have ultimate stretch resistance ensuring that its designed shape would keep as long as possible. It would be impervious to UV rays, salt water, and humidity. It would last forever and, of course, it would be affordable.

But unfortunately, no one material lives up to all these conditions, and the trick to selecting the best sail for you and your boat is to determine which of these qualities are most important to you.

Sailcloth Constructions

When talking sailcloth materials, it is important to differentiate between construction types and fiber materials. Woven, laminate, and 3Di are all sailcloth constructions, and within each category, various fiber materials, such as nylon, polyester, and carbon, are used.

Let’s first take a look at sail the different types of sail constructions, to help you get a better idea of how sailcloth is made to suit different sailing applications.

Paneled Woven Cloth

Woven fabrics, usually made of polyester (Dacron) are still to this day the most common construction for sailcloth, widely used in all sailing applications. This is mainly due to its durable and lightweight properties and the fact that it is the most affordable option.

However, a downside to woven sailcloth is its elasticity, caused by the crimp, (the over-and-under nature of the weave) and over time the sail will inevitably lose shape and start sagging.

Although modern-day sailcloth manufacturers have gotten exceptionally good at minimizing this effect through chemical treatments and heat shrinking, when it comes to shape retention, woven sailcloth does not compete with alternative high-performance constructions such as laminate and 3D composites.

Paneled Laminate

Laminate sails are a modern-day art and have in the last few decades become very popular, especially with the racing crowd. This is due to their high durability and exceptional shape retention; attributes which are often at the top of the priority list of the avid racer.

Because of their significantly higher cost and shorter life span, cruising sailors have traditionally had apprehensions about this construction. But slowly, even this is changing, and cruisers are beginning to open their eyes to the great values of these high-performance sails.

When building laminate sails, various materials and building techniques can be used. But generally speaking, laminate sails are a sandwich construction, laminating fibers or scrim protected with mylar film between one or two taffeta layers. The core fibers can be of various materials, such as polyester, aramid, or carbon, having different effects on the overall strength and weight of the finished cloth.

There is no doubt that, when it comes to both durability and shape retention, laminates by far surpass woven materials. In laminates, the fibers are laid on top of each other, they are not woven, eliminating the stretch that in woven sails is caused by the crimp. The fibers are also less stretchy and can be laid more intentionally to add strength where the loads on the sail are greater.

Membrane Sails

Although a type of laminate sail, membrane sails differ in the way they are built. Whereas laminate sails are made from rolls of prefabricated laminate sailcloth, the membrane sail is made ‘from scratch’, putting together the fibers to make the fabric at the same time as building the sail.

This building method permits the sailmaker to be specific in fiber density across the sail, to match the expected loads put on the sail when in use. These fully custom-made sails are a step up from laminates when it comes to both strength, shape retention, and price. Popular brands making racing membrane sails are Quantum Sails, Doyle Sails, UK Sailmakers and others.

3D Molded Composite / North Sails 3Di

3Di sails, a trademark construction developed by sailmaker North Sails, is a relatively new technology, but one which has found its place at the very top of the range when comparing high-performance sails.

Unlike paneled sails which are built on a flat surface, 3Di sails are built, much like a hull or an airplane wing, using a 3D mold. But, just like traditional sailcloth, 3Di sails are made using fibers or filaments (70% of the sail structure), and resin (30% of the sail structure).

The filaments used in constructing 3Di sails can be of various materials enhancing different qualities to suit different sailing applications. But the art is in the construction, and it is the way that North Sail use the different materials that sets them apart from other sail constructions.

First, the layout of the sail is determined, drawing out the sail’s size, shape, batten pockets, and reef points. Then the 3D mold will be adjusted exactly to these specifications.

The sails’ structure is made from ultra-thin, resin-impregnated filament tapes laid out on the 3D mold slightly overlapping to form a whole fabric. It is then heat treated to cure the resin before the sail is removed from the form and the sailmaker does his finishing touches.

A huge advantage of 3Di sails is that it does not require the use of mylar film, making the 3Di sail superior to laminates in weight and longevity as there is no concern for delamination.

Fiber Materials

Now you have a better grasp of the different sailcloth constructions, let’s take a look at the individual fiber materials. This should help you get a better understanding of the qualities and weaknesses of each material when applied to different constructions.

Polyester (Dacron)

Polyester or better known by DuPont’s Trademark name Dacron® is still one of the most used materials in the making of woven sails due to its durability, excellent UV resistance, and longevity.

Furthermore, for many sailors the woven Dacron sailcloth, still illustrates the best value for money, with many sailors reporting that their sails are lasting more than 20 years.

The least expensive laminate cloth is made from polyester, and although significantly better than woven polyester cloth, it is the lowest on the scale of stretch resistance when talking laminate sails.

Aramid

Aramid, short for aromatic polyamide, covers various para-aramids or trademark brands such as Kevlar®, Twaron®, and Technora®.

With a tensile strength equivalent to that of steel, aramid is a very popular material used in making both woven and laminate sails. It is lightweight, very strong, and flexible, and with a much better stretch resistance than polyester, it is a preferred material among many racers.

One downside to aramid is its very poor resistance to UV damage and it is therefore often coated with other protective composites.

Aramid is of midrange cost, and more expensive than polyester. However, this is often justified by its longer lifespan and better shape retention.

Vectran Fiber

Based on polyester with an aramid-type molecular structure, Vectran fiber combines the advantages of both materials. With a focus on durability, Vectran is especially popular with performance cruisers, but due to its inferior stretch resistance compared to pure Aramid, it is not the preferred material for high-performance racers.

Ultra PE (UHMWPE)

Ultra-high molecular weight polyethylene, better known by its trademark names Dyneema® or Spectra®, is renowned for its exceptional breaking strength.

However, under permanent load, the Dyneema fibers do tend to elongate, causing the sail to lose some shape.

Dyneema is especially popular for larger cruising boats where strength and durability are paramount. The high cost of Dyneema is often justified by its excellent strength and good resistance to UV and fatigue ensuring a long sail life.

Carbon Fiber

Another material very popular in the use of both laminate and 3Di sails, carbon has exceptional resistance to both UV and stretch. However, carbon is extremely sensitive to flex and this needs to be considered in sail handling, and flogging should be avoided as best as possible. To give it better flex, carbon is often mixed with the more flexible Ultra PE (Dyneema).

Conclusion

Just like there is a wide range in sail performance so there is in price, and one of the first questions you should ask yourself is, what do you want from a sail and how much money are you willing to pay for it?

Secondly, you should consider your sailing application. Are you a casual sailor looking for a sail to get you across the bay, a long-distance cruiser looking for a sail to last across oceans, or are you a competitive racer looking to outshine your rivals?

The ideal sailcloth material is not necessarily the finest on the market, but the one that lives up to your specific expectations to suit your boat and sailing application.